Scheduled Outages in Renewable Power Plants Save Time, Effort and Dollars

Outages are a necessity despite putting a pause on availability—but when you plan for them, you minimize risks and ultimately can extend the operational lifetime of your equipment

Planned outages are the optimal way to ensure the proper repair, overhaul or replacement of turbine parts as part of a sound power generation maintenance strategy. By identifying the scope or work, evaluating the parts and service needed, and executing to ensure the work is done effectively to ensure your gas or steam turbine becomes available as quickly as possible.

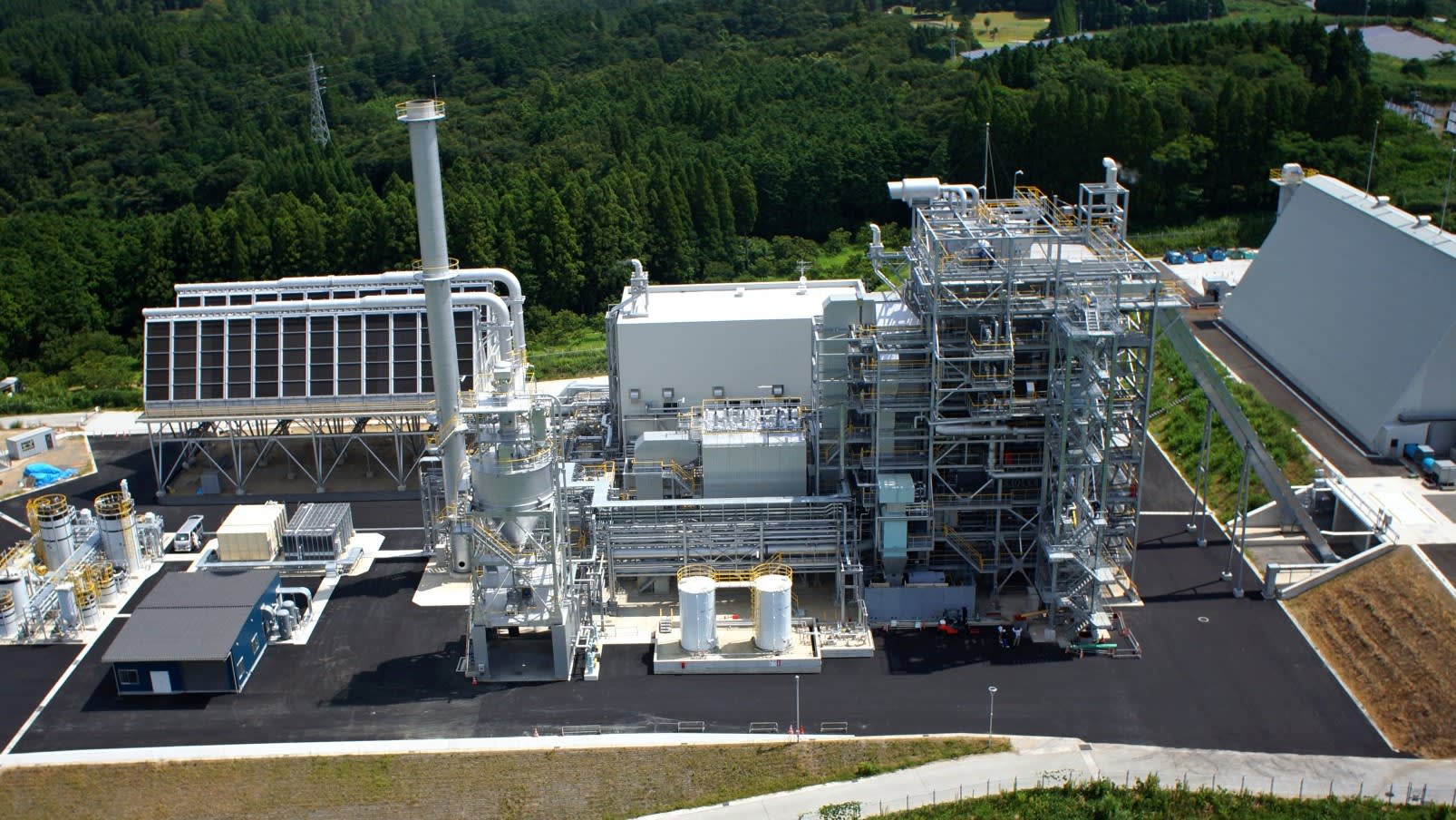

Power generating equipment in Waste-to-Energy (WtE) and biomass power plants are no different than that employed in conventional coal, natural gas or nuclear energy. The execution of a well-planned scheduled outage minimizes its effect in the overall operation since it allows for proactive maintenance that can highly reduce or eliminates an unplanned shutdown.

Common reasons for unplanned outages are a failure to execute a proper maintenance plan, which in turn can create vulnerabilities that can trigger a shutdown—either during high-demand periods—particularly during a cold winter, a scorching summer or during a strong weather event, such as severe thunderstorms.

As a best practice, once a planned shutdown is complete a biomass or WtE power plant its managers should begin planning the next—all part of an ever-renewing cycle of preventive maintenance across the entire system. Case in point, many steam turbine parts require periodic replacement, which is identified during a planned outage.

Having a long-term maintenance strategy allows WtE and biomass power plant personnel to prepare ahead of time, review technical safety standards (including OSHA safe operating procedures), and hold inspections before the steam turbine outage is executed. Hence, being proactive pays off and helps anticipate the need to replace such power generation equipment due to its tear and wear.

Again, all of these efforts aim at identifying what parts or components should be replaced during a planned outage in an effort to prevent an unplanned outage that can be costlier in terms of time, effort and cost.

Prime Turbine Parts works closely with power plant managers and field engineers involved in planned outage events, ready to supply parts and other consumables. Our ability to source these parts and to actively anticipate the needs of customers makes our company the perfect complement for their WtE and biomass power plant operation.

Contact Prime Turbine Parts today to explore consumable Steam Turbine parts for WtE and biomass power generation facilities.